Quality Control

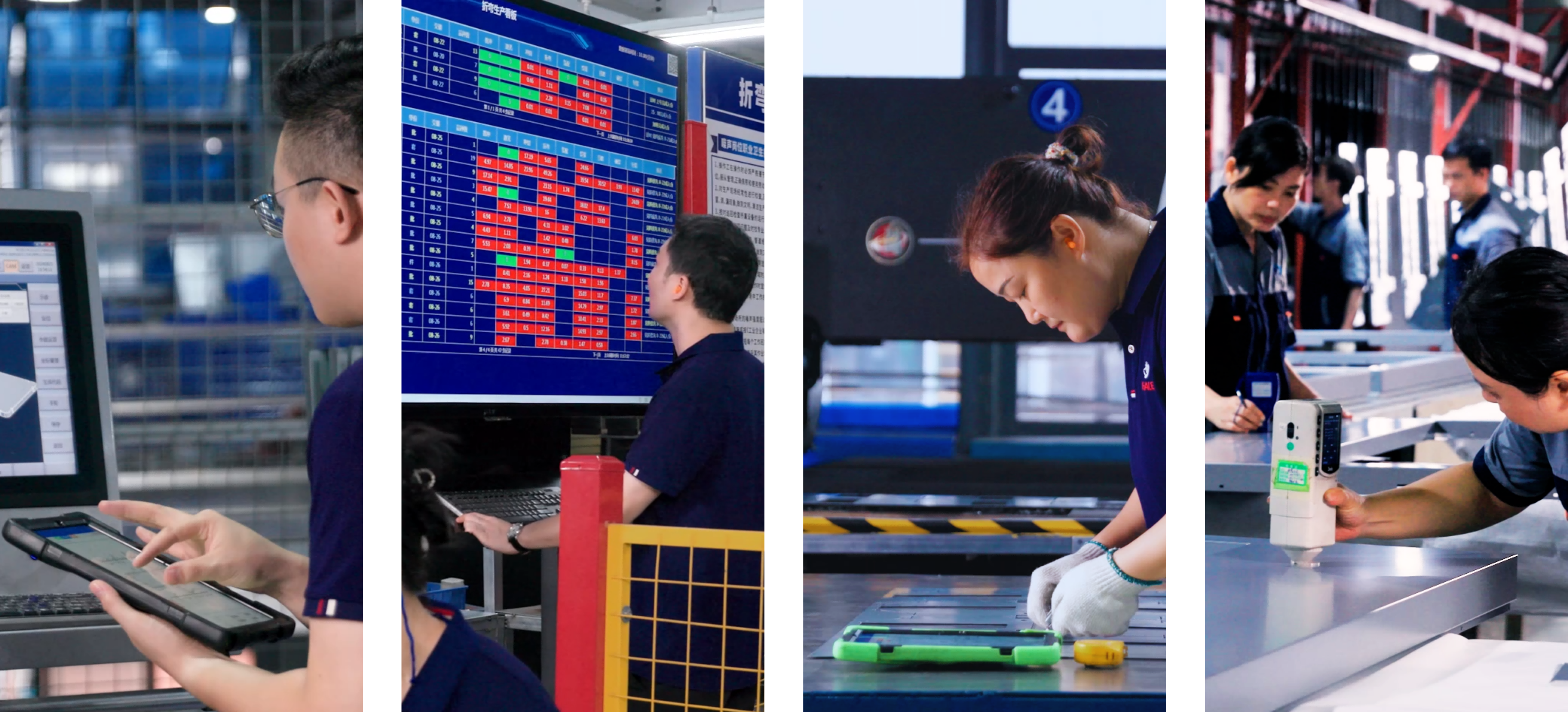

Total Quality Control for Sheet Metal EnclosuresReal-Time Monitoring, Long-Term Reliability In sheet metal manufacturing, quality isn't just a final check — it's a built-in discipline at every stage. We implement full-process quality control with real-time production data monitoring and corrosion resistance validation to ensure every enclosure is built to last. |

|

|

Highlights of Our Quality Management System1. Salt Spray Testing for Surface Durability 2. Digital Production Dashboards 3. Integrated QC Across All Stages 4. Traceable, Measurable, Reliable |

RELATED PRODUCTS

Online Message

Fill in the relevant information on this page and submit it. A member of staff will contact you immediately, or call us directly.